The mechanical engineering is a traditional field, however, the related research topics are recently of interest and under development in the global scenario.

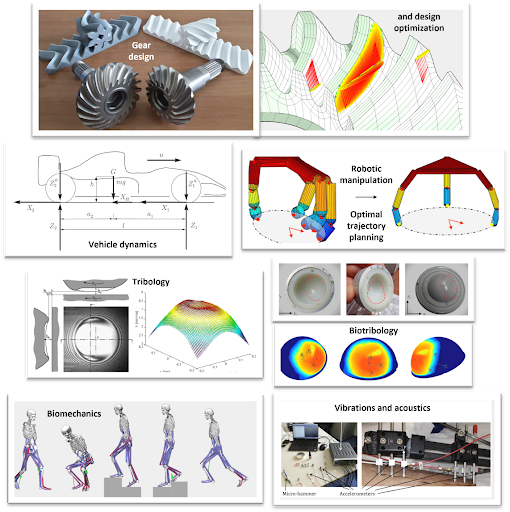

At DICI department there are several activities on mechanical research, such as strength of materials and mechanical components, dynamic responses of structures, transmission gears, traditional and innovative manufacturing processes (such as additive manufacturing), robotics, mechanical bioengineering, tribology, and others.

These research fields are implemented both from the experimental and the modelling point of views, using recent and innovative experimental techniques and advanced calculation software.

The mechanical research at the DICI department is usually developed in collaboration with companies, either local or multinational, and international institutions, with which long-lasting and successful collaborations and projects are generated.

Main Research Activities

Material strength characterization

The determination of the strength properties of materials is a research topic that is usually performed by mechanical engineering professors involved in Machine Design. The recent developments of the modelling of materials requires both the ability to perform traditional tests, imposed by standards, and also the conception and implementation of innovative tests on non-conventional specimens or even tests on the actual components replicating the applied loads. The laboratory dedicated to this testing activity, at the DICI dept., is equipped with several testing machines and structures, that are more typically suited for metals but can be used for other materials too. In this testing facility, there are three hydraulic universal testing machines (one of them biaxial), two resonant fatigue testing machines, and a large bench with three axial instrumented actuators, that allows full scale tests on components such as motorcycle frames. In addition to the testing facility there are some machine tools for the manufacturing of the specimens or any required support parts for the tests. Moreover, there is an Additive Manufacturing machine (SLM) for metals, with a dedicated furnace for heat treatments. In the research field of material resistance, innovative manufacturing techniques, such as the additive, are quite attractive nowadays, since they are quite challenging for the modelling tasks being non-traditional materials.

Labs

Automotive design

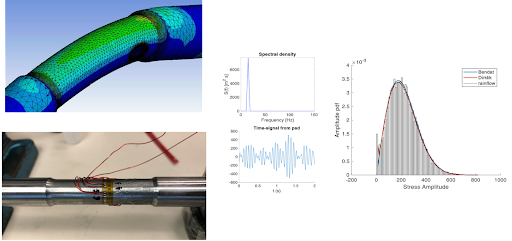

The structural and dynamic characteristics of vehicles and components is a research topic studied by the professors of Machine Design by means of analytical and numerical models and experimental tests. Indeed, many vehicle components have to be simulated and tested using specially developed models and test benches. Regarding the simulations, the group deals with developing original analytical models (e.g. brush model for transmission belts) for the analysis of the mechanical behavior and efficiency of the systems, and numerical models (FEM and multibody) able to predict the dynamic behavior, vibrations, static and fatigue resistance of the components. The experimental tests foresee the use of universal testing machines (tension and torsion), resonance machines and the development of ad-hoc test benches with hydraulic actuators, electric motors, and several types of sensors. The aim of the experimental activity is the test (resistance, durability, etc.) of the components subjected to real loads, even random loads, and at the validation of the analytical and numerical models. For both numerical and experimental analyses, the group develops methods for the prediction of the life of the components both using classical methods (rainflow and damage accumulation) and "frequency fatigue" methods, which take into account the spectrum (PSD and pdf) of the loads and are able to accurately predict the life of the components and to optimize their shape to reduce the weight.

Labs:

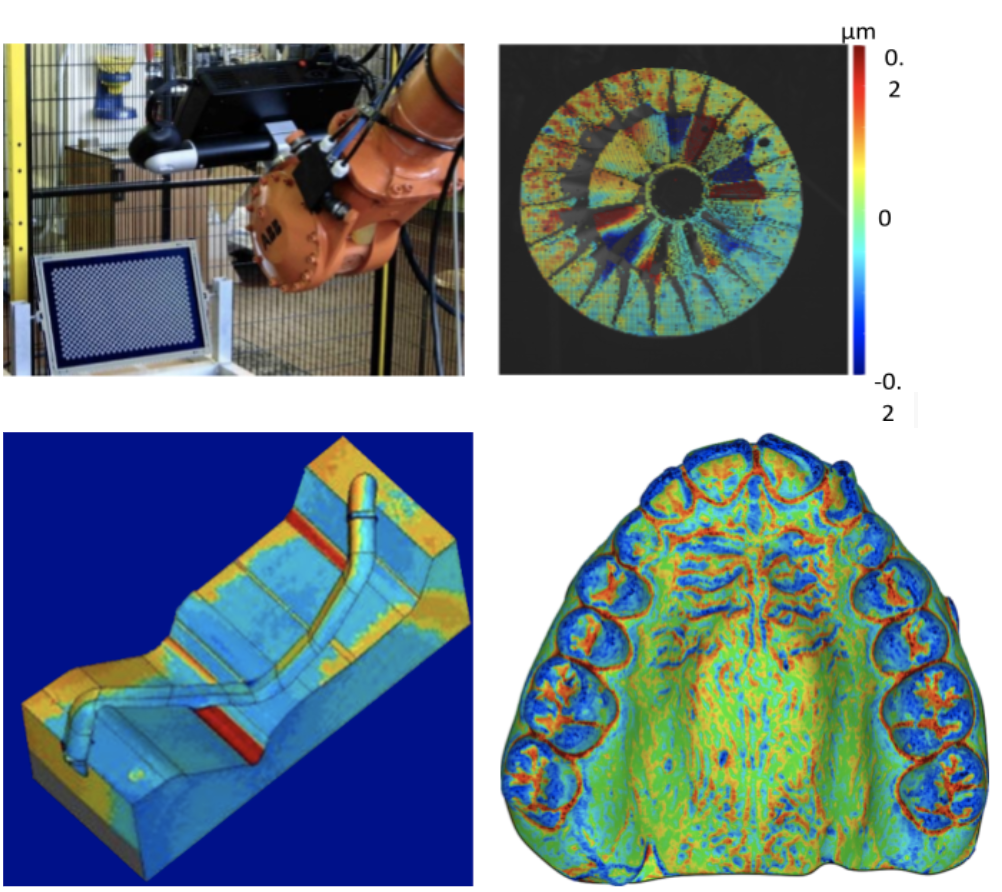

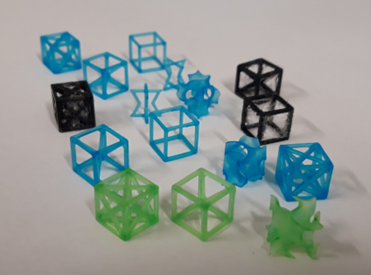

Reverse engineering, Experimental dynamics, Design for additive manufacturing, and Extended reality

Research activities are oriented toward the development of image processing and reverse engineering techniques for the reconstruction of complex 3D shapes and deformations in industrial and biomedical fields. 3D optical scanners based on structured light-based sensing have been implemented and are effectively used for metrology applications in precision mechanics and patient anatomy reconstruction in the biomedical field. Such an approach was further developed by integrating the Digital Image Correlation technique, which allows for assessing mechanical components’ deformation during dynamic excitation. The developed system allowed for vibration measurements in the range of 10 µm and 6500 Hz. Current research interests are also oriented toward the study and optimization of process parameters of additive manufacturing (AM) technologies, with a particular focus on polymeric materials. The research activity includes the mechanical characterization of AM components, the use of specifically developed post-processing treatments and coating to enhance AM parts performances, and the development of lightweight AM lattice structures. Research topics also include the experimentation of hybrid AM techniques which extend the use of technologies developed for polymers to the manufacturing of metal and ceramic components. Finally, emerging research activities include the development of virtual, augmented, and mixed reality applications in different fields including rehabilitation and cultural heritage.

Labs:

3D Printing

Manufacturing and processing technologies

The Manufacturing Technology and Systems group performs scientific research in the context of material transformation processes for the production of semi-finished and finished components in order to study the entire life cycle of products from their design to production and recycling.

The main subject of the group's research activity is analysis of the various stages of the production process and its optimization both for conventional manufacturing processes and innovative processing systems based on energy intensification. Research activity also includes the management and organization of transformation processes including both physical and digital aspects.

The group boasts many years of experience in the field of transformation processes involving manufactured products made up of traditional and innovative materials, ranging from manufacturing to assembly and quality control. Further expertise includes metrological and technological characterization of materials, correlation of properties with process parameters, methodologies and tools for the design of processes, components and transformation systems, and programming, management and control of processing and flexible assembly systems.

Labs:

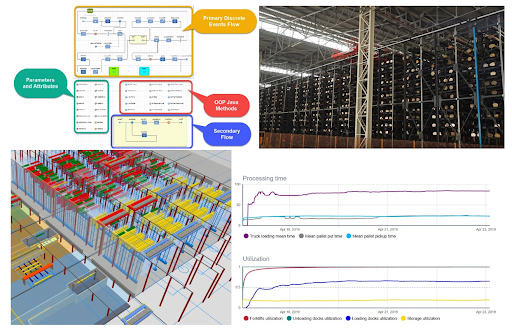

Mechanical industrial plants

The research group of Mechanical Industrial Plants (ING-IND/17) of the University of Pisa is chiefly interested in Lean and Agile Management, with particular reference to Engineering and Design To Order (ETO, DTO) companies, vertical and horizontal integration as an enabling factor of Industry 4.0 and the digitalization of production and logistics processes. The aim of the studies is to define, implement, optimize and support the digital transformation processes that allow traditional production and logistics systems to evolve respectively into smart factories and smart supply chains. Further activities concern the study, the implementation and the optimization of Quick Response Manufacturing and Quick Response Logistics systems. The scope of these researches also extends to Data Analytics for predictive maintenance and prognostics and to plant simulation (with simulation tools for discrete events, agents and system dynamics models). This last theme, already strongly linked to the Industry 4.0 paradigm, has been recently combined with the study and the prototyping of process digital twins.

Applied mechanics

The Applied Mechanics group carries out research on the following topics

- Optimal design of gears for power transmission, in particular spiral bevel and hypoid gears.

- Vehicle dynamics. From the innovative approach to vehicle dynamics by Massimo Guiggiani to optimal trajectory planning of racing vehicles.

- Artificial hands, robotic manipulation, optimal control. Development of robotic hands on the basis of postural synergies. Automatic grasp synthesis, later extended to complex manipulation tasks and whole-body locomotion.

- Tribology. Lubrication, friction, wear, and surface analysis. The Tribology Laboratory conducts tests on lubricated and dry contacts, while the Rotordynamics and Bearings Laboratory investigates the static/dynamic behavior of bearings.

- Biotribology. Estimation of wear in joint prostheses through analytical/FEM models and analysis of worn components using a 3D profilometer, CMM, and SEM

- Biomechanics. Development of musculoskeletal models for the estimation of quantities that are not measurable in vivo. Motion analysis at the Sport & Anatomy Biomechanics Laboratory.

- Vibrations and acoustics. Numerical-experimental characterization of the vibrational response of various systems. Psychoacoustic evaluation of the sound quality of products.

Labs: